At Petra Gems, after finishing the jewelry, we often send

pictures to the client for review before shipment. Additionally, we provide a

beautiful jewelry box with each design to enhance the presentation.

If desired, we can also provide an appraisal for the

jewelry, detailing the description and value of the item, as well as specifying

the type of metal used in the production process and the grading of the

diamonds or other gemstones.

Client satisfaction is our top priority, and we encourage

our clients to reach out and ask questions before making a final decision. We

believe in empowering our clients with knowledge about the process and the elements

of creating their custom pieces.

Moreover, we aim to provide comprehensive information on

gemstones and diamonds so that your purchase is not just a luxury item but also

an investment.

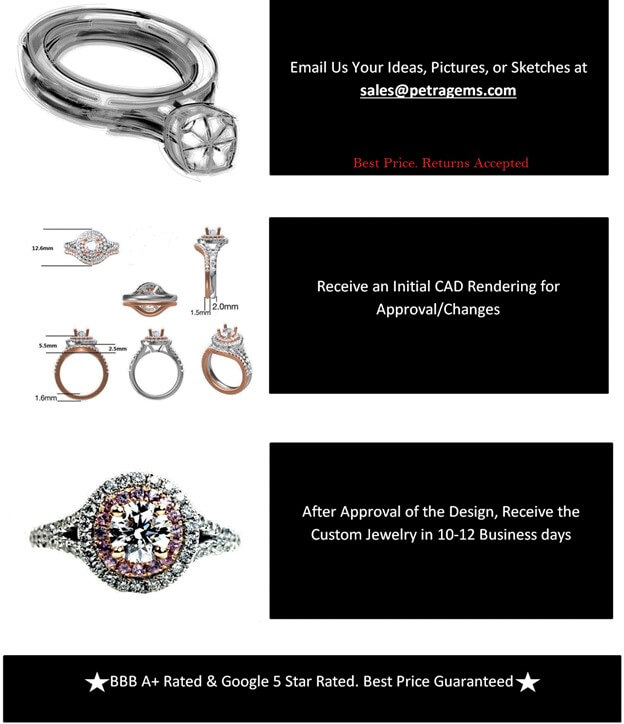

At Petra Gems, we take pride in our decade-long service to

clients, consistently receiving five-star ratings on Google, the Better

Business Bureau (BBB), Yelp, Wedding Wire, and Etsy. This demonstrates our

unwavering commitment to quality and customer service. Few companies can boast

such an exceptional rating.

While our primary focus is on publishing content related to

diamonds and fine jewelry, we are happy to work on a case-by-case basis with

clients who want 100% custom-designed jewelry.